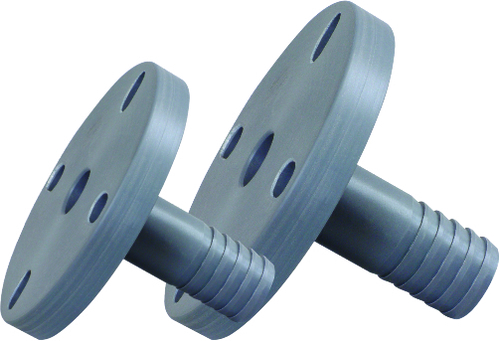

PP / HDPE Long Neck with Flange

PP / HDPE Long Neck with Flange Specification

- Yield Strength

- PP: 20-22 MPa, HDPE: 21-29 MPa

- Diameter

- DN 50 to DN 300 (2 to 12)

- Sealing Type

- Gasket Required (not supplied)

- Coating Type

- Uncoated

- Flexibility

- Rigid

- Tensile Strength

- PP: 29 MPa, HDPE: 25-31 MPa

- Connection Type

- Bolted Flange Joint

- Tolerance

- 1 mm

- Temperature Range

- -20C to +80C

- Thread Type

- Not Threaded

- Product Type

- Long Neck with Flange

- Material

- PP / HDPE (Polypropylene / High-Density Polyethylene)

- Connection

- Flanged

- Shape

- Cylindrical with Flanged End

- Standard

- IS 8008 / DIN 8063 or as per customer requirement

- Surface Treatment

- Smooth / Plain

- Outer Diameter

- 63 mm to 400 mm

- Section Shape

- Round

- Length

- 150 mm to 600 mm (custom lengths available)

- Thickness

- 3 mm to 15 mm (as per size and application)

- Color

- Black, White, Grey (custom colors available)

- Usage

- Piping, Chemical Line, Water Supply, Effluent Handling

- Rated Pressure

- PN 6, PN 10 (as per requirement)

- Material Grade

- Virgin / Industrial Grade

- Application

- Industrial Pipeline, Chemical Process Lines, Water Treatment Plants

About PP / HDPE Long Neck with Flange

PP HDPE Extra Long neck with Flange

Available MOC PP POLYPROPYLENE HDPE HIGH DENSITY POLYETHYLENE

SIZE

CODE

IN MM

1 32 P1ELF01

1 12 50 P1ELF02

2 63 P1ELF04

3 90 P1ELF05

4 90 P1ELF06

MAXWORKING PRESSURE 10Kg CM2

Versatile Applications and Customization

PP / HDPE Long Neck with Flange fittings are widely used in industrial pipelines, chemical process systems, water supply, and effluent handling projects. They are available in various diameters, thicknesses, and lengths to match diverse requirements. Custom options for color, material grade, and standards (including IS 8008, DIN 8063) ensure perfect compatibility and performance within any installation environment.

Durability and Performance

These fittings are engineered using virgin or industrial-grade PP and HDPE, offering high tensile and yield strength, excellent resistance to acids, alkalis, and solvents, and reliable performance between -20C and +80C. The construction is rigid and non-brittle, with optional UV stabilization for outdoor use, ensuring long service life and reduced maintenance in harsh conditions.

Manufacturing and Quality Assurance

Each long neck flange is manufactured using advanced injection or fabricated molding techniques. Quality is rigorously maintained with hydrostatic leak testing and tight dimensional tolerance (1 mm). The smooth finish and consistent wall thickness (3 mm to 15 mm) further guarantee dependable installation and operational safety for end users.

FAQ's of PP / HDPE Long Neck with Flange:

Q: How are the PP / HDPE Long Neck with Flange products typically used in industrial settings?

A: These long neck flanges are primarily utilized for connecting pipelines in chemical process plants, water treatment facilities, and effluent handling systems, ensuring a reliable and leak-resistant transition joint where secure bolted flange connections are required.Q: What customization options are available for the long neck with flange?

A: Customers can specify nominal bore, length (150 mm to 600 mm), color (black, white, grey, custom), material grade, outer diameter (63 mm to 400 mm), flange standard (ANSI, DIN, BS), and pressure rating (PN 6 or PN 10) to match their project requirements.Q: Where are these flanged fittings most beneficial to use?

A: They are ideal in environments that demand excellent chemical resistance, such as chemical pipelines, water supply lines, and industrial effluent systems, particularly where corrosion and impact strength are critical concerns.Q: What manufacturing processes are involved in producing these products?

A: The flanges are produced using either precision injection molding or fabricated molding techniques, ensuring consistent dimensional accuracy and strong structural integrity tailored to application needs.Q: What benefits do PP / HDPE long neck flanges offer over traditional metal flanges?

A: These fittings provide outstanding resistance to chemicals and corrosion, high impact strength without brittleness, lighter weight for easier handling, and lower maintenance demands compared to metal counterparts, making them cost-effective and long-lasting in corrosive or water-based systems.Q: How is the quality and leak resistance of the product ensured?

A: Each unit undergoes hydrostatic pressure leak testing, and is produced within tight dimensional tolerances (1 mm). A gasket is required for optimal sealing at the flange connection, though not supplied with the product.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Pipe Fitting Category

Electrofution Reducer

Price 204 INR / Piece

Minimum Order Quantity : 50 Pieces

Coating Type : HDPE

Pressure Ratings : 16Kg

Product Type : Other

Material : HDPE

Electrofusion Bend 45*

Price 85 INR / Piece

Minimum Order Quantity : 50 Pieces

Coating Type : HDPE

Pressure Ratings : 16Kg

Product Type : Elbow

Material : HDPE

Electrofusion Tee

Price 90.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Coating Type : HDPE

Pressure Ratings : 16Kg

Product Type : Tee

Material : HDPE

Electrofusion Coupler

Price 96.0 INR / Piece

Minimum Order Quantity : 50

Coating Type : HDPE

Pressure Ratings : 16Kg

Product Type : Coupling

Material : HDPE

|

Parth Poly Valves Private Limited

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry